Hardness testing to ISO 6508-1

Call anytime

Call anytime

Send email

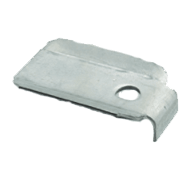

Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance and high strength. Manway lock clamps made from Monel 400 are used in various industrial applications, particularly in environments where resistance to corrosive elements is essential.

Here are some key features, applications, machining considerations, and heat treatment information related to Monel 400 manway lock clamps:

Features:

1.Corrosion Resistance: Monel 400 is highly resistant to corrosion by

various media, including seawater, sulfuric acid, hydrofluoric acid, and

alkaline solutions. This makes it suitable for use in harsh, corrosive

environments.

2.High Strength: Monel 400 offers good mechanical properties, making it

capable of withstanding high-stress applications.

3.Excellent Ductility: It has good ductility, which allows for various

fabrication processes, including forging, welding, and machining.

4.Low Magnetic Permeability: Monel 400 exhibits low magnetic

permeability, which can be advantageous in certain applications.

Applications: Monel 400 manway lock clamps find applications in industries where corrosion resistance and durability are crucial. Some common applications include:

1.Marine Equipment: Manway lock clamps are used in shipbuilding and

offshore structures due to Monel 400's resistance to seawater corrosion.

2.Chemical Processing: Monel 400 is utilized in the production of

chemicals, especially those involving sulfuric acid, hydrofluoric acid, and

caustic solutions.

3.Oil and Gas: It is used in equipment such as valves, pumps, and flanges

in the oil and gas industry, particularly for components exposed to corrosive

hydrocarbons.

4.Aerospace: Monel 400 Manway lock clamps can be found in aircraft

components due to their strength and corrosion resistance.

Machining: Machining Monel 400 can be challenging due to its hardness and the tendency to work harder. Here are some considerations for machining Monel 400:

1.Carbide tools are typically used for turning, milling, and drilling Monel

400, as they offer better performance and tool life.

2.A slow cutting speed and high feed rate are recommended to minimize heat

generation, as excessive heat can cause work hardening and tool wear.

3.Adequate cooling and lubrication should be used to control temperature

during machining.

4.Sharp cutting tools and proper tool geometry are important to achieve good

surface finishes.

| Specifications | ASTM B164 / ASME SB164 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

Heat Treatment: Monel 400 Manway lock clamps are typically used in the annealed condition for most applications. Heat treatment is not commonly applied to this alloy. Annealing is performed at temperatures between 1600°F (870°C) and 1900°F (1040°C), followed by a water quench or rapid air cooling. Annealing helps relieve stresses and enhance its mechanical properties.

It's important to note that Monel 400 Manway lock clamps are known for their good performance in various environments without the need for additional heat treatments. The specific heat treatment requirements, if any, may depend on the specific application and the desired material properties.

To preserve the high standards of our selection of industrial Manway Lock clamps, we have always adhered to a systematic quality management process.

Our staff of experts is vibrant and talented, and they have always been our largest supporters and contributors to our success. Our vision is to create a world of Manway Lock clamps.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Hardness testing to ISO 6508-1

Nut proof load testing to ISO 898-2

Suitability for preloading to EN 14399-2

Calibrated gauges and tools

| Monel 400 Manway Lock Clamp Suppliers in India | Monel Alloy 400 Manway Lock Clamps Manufacturer in India |

| 400 Monel Manway Lock Clamp Manufacturer in Mumbai | ASTM B164 400 Monel Manway Lock Clamp |

| UNS N04400 Manway Lock Clamps | Monel 400 Manway Lock Clamps Manufacturer in Mumbai |

| Monel 1.4301 Manway Lock Clamps | Monel 400 Manway Lock Clamp Price |

| Monel 400 Manway Lock Clamps Manufacturers in Mumbai | 400 Monel Manway Lock Clamps |

| 400 Monel Alloy Manway Lock Clamps | Monel 400 Manway Lock Clamp Suppliers in Mumbai |

| Monel 400 Manway Lock Clamp Supplier in Mumbai | 400 Monel Manway Lock Clamp Manufacturer |

| 400 Monel Manway Lock Clamp Manufacturer in India | Best Monel 400 Manway Lock Clamps |

| Monel 400 Manway Lock Clamp Supplier in India | Monel Alloy 400 Manway Lock Clamps Price List |