Hardness testing to ISO 6508-1

Call anytime

+91 22 6659 5948Call anytime

+91 22 6659 5948Send email

[email protected]Ti Grade 2 Fasteners are manufactured from 99% pure titanium. Titanium gr 2 fasteners are used in various applications and have high corrosion resistance. They can withstand high pressure and temperature. These fasteners are light and low-density. Titanium Gr.2 Fasteners are exceptionally resistant to salt water and brine, which makes them perfect for marine applications.

Titanium fasteners also have excellent resistance to oxidation because they have a strong oxide layer that regenerates when exposed to oxygen. Grade 2 Titanium Fasteners are a popular choice for many fasteners because they have excellent corrosion resistance and strength. Titanium grade 2 material fasteners are available in various forms and are useful in industrial, marine, chemical processing, and desalination applications. Titanium gr 2 bolts and nuts resist oxidizing media, alkalis, organic acids, chlorine chemicals, and salt solutions. As a leading titanium fasteners manufacturer, Vision Alloys also produces other premium products like Inconel 718 Fasteners and SS 304L Fasteners to meet the unique requirements of our clients.

Titanium-grade fasteners are also resistant to oxidation & offer superior resistance to various corrosive environments, including seawater, chlorine gas, sulfur dioxide, & hydrogen sulfide. It can resist heat & hot gas. When ASTM B348 UNS R50400 fasteners are exposed to an oxygen-containing atmosphere, they instantly acquire a thin, tenacious layer of oxide that protects them from corrosion & offers excellent resistance to oxidation.

Vision Alloys is a trusted Titanium Gr 2 Fasteners Supplier in India. We deliver high-quality products for applications such as wastewater recovery systems, ClO2 generators, hydrocarbon processing, marine engines, and chemical processes. We ensure competitive rates for all our offerings, with prices starting at approximately ₹600 to ₹900 per kilogram (subject to market fluctuations).

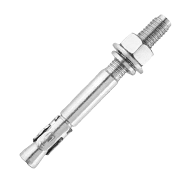

Grade 2 Titanium Anchor Bolt or Grade 2 Titanium Fasteners are a good choice for many industrial applications and are widely used in wastewater recovery systems, ClO2 generators, hydrocarbon processing, marine engines, and chemical processes. Titanium Alloy Gr 2 Fasteners offer several benefits, including a high strength-to-weight ratio and superior corrosion resistance.

Titanium Grade 2 Material is renowned for its high strength-to-weight ratio and corrosion resistance. Unlike stainless steel, titanium fasteners are non-magnetic, making them ideal for medical and electronic equipment where magnetic interference could pose issues. The corrosion-resistant nature of Titanium Gr 2 Fasteners makes them highly suitable for construction and piping projects involving aggressive chemicals like chlorine dioxide.

| Specifications | ASTM B348, ASME SB348 |

| Standard | DIN, ASTM, BS and all International Standards |

| Size | M3 to M90 |

| Length | 10mm to 1000mm |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr.2 | 3.7035 | R50400 |

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade 2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | - | - |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Ti Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

Titanium Gr 2 Nuts

Titanium Gr 2 Nuts

Titanium Alloy Gr 2 Bolt

Titanium Alloy Gr 2 Bolt

Titanium Gr 2 Washer

Titanium Gr 2 Washer

Gr 2 Titanium Stud Bolts

Gr 2 Titanium Stud Bolts

Titanium Gr 2 Hex Bolt

Titanium Gr 2 Hex Bolt

Ti Gr 2 Threaded Rod

Ti Gr 2 Threaded Rod

Gr 2 Ti Anchor Bolt

Gr 2 Ti Anchor Bolt

Gr 2 Alloy Spring Washer

Gr 2 Alloy Spring Washer

| INCH SIZE | METRIC SIZE | DECIMAL (INCH) | MILLIMETER (mm) |

| M6 | .2362 | 6.0000 | |

| 1/4 | .2500 | 6.3500 | |

| 5/16 | .3125 | 7.9375 | |

| M8 | .3149 | 8.0000 | |

| 3/8 | .3750 | 9.5250 | |

| M10 | .3937 | 10.0000 | |

| 7/16 | .4375 | 11.1125 | |

| M12 | .4724 | 12.0000 | |

| 1/2 | .5000 | 12.7000 | |

| 9/16 | .5625 | 14.2875 | |

| 5/8 | .6250 | 15.8750 | |

| M16 | .6299 | 16.0000 | |

| 3/4 | .7500 | 19.0500 | |

| M20 | .7874 | 20.0000 | |

| 7/8 | .8750 | 22.2250 | |

| M24 | .9448 | 24.0000 | |

| 1 | 1.0000 | 25.4000 | |

| 1 1/8 | 1.1250 | 28.5750 | |

| M30 | 1.1811 | 30.0000 | |

| 1 1/4 | 1.2500 | 31.7500 | |

| M36 | 1.4173 | 32.0000 | |

| 1 1/2 | 1.5000 | 38.1000 | |

| M42 | 1.6535 | 42.0000 | |

| 1 3/4 | 1.7500 | 44.4500 | |

| M48 | 1.8898 | 48.0000 | |

| 2 | 2.0000 | 50.8000 | |

| M56 | 2.2047 | 56.0000 | |

| 2 1/2 | 2.5000 | 63.5000 | |

| 3 | 3.0000 | 76.2000 |

| Size | Square | Heavy Hex | Finished Jam | Finished Hex | Heavy Square | Heavy Hex Jam |

| 1/2″ | 5.78 | 6.54 | 2.62 | 3.75 | 7.87 | 4.00 |

| 5/8″ | 10.8 | 11.9 | 4.93 | 7.33 | 14.3 | 6.96 |

| 3/4″ | 15.4 | 19.3 | 7.70 | 11.9 | 23.5 | 11.0 |

| 7/8″ | 24.5 | 29.7 | 12.0 | 19.0 | 36.2 | 16.7 |

| 1″ | 36.3 | 42.5 | 17.6 | 28.3 | 51.5 | 23.5 |

| 11/8″ | 52.5 | 59.2 | 24.7 | 40.3 | 72.4 | 32.4 |

| 11/4″ | 70.6 | 78.6 | 36.1 | 54.3 | 95.5 | 45.8 |

| 13/8″ | 94.5 | 102 | 47.9 | 73.0 | 125.0 | 59.3 |

| 11/2″ | 122 | 131 | 60.9 | 94.3 | 161 | 74.8 |

| 15/8″ | 162 | 91.6 | ||||

| 13/4″ | 204 | 100 | 151 | 114 | ||

| 17/8″ | 241 | 134 | ||||

| 2″ | 299 | 140 | 224 | 165 | ||

| 21/4″ | 419 | 227 | ||||

| 21/2″ | 564 | 332 | ||||

| 23/4″ | 738 | 429 | ||||

| 3″ | 950 | 545 | ||||

| 31/4″ | 1194 | 651 | ||||

| 31/2″ | 1526 | 851 | ||||

| 33/4″ | 1812 | 1005 | ||||

| 4″ | 2180 | 1200 |

| BODY DIAMETER | HEAD THICKNESS ASTM A193 |

ACROSS ASTM A193 FLATS |

ACROSS ASTM A193 CORNERS |

|||||

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

To preserve the high standards of our selection of industrial fasteners, we have always adhered to a systematic quality management process.

Our staff of experts is vibrant and talented, and they have always been our largest supporters and contributors to our success. Our vision is to create a world of fasteners.

Hardness testing to ISO 6508-1

Nut proof load testing to ISO 898-2

Suitability for preloading to EN 14399-2

Calibrated gauges and tools

| UNS R50400 Hex Head Fasteners | Ti Gr 2 Nuts and Fasteners |

| Grade 2 Titanium Hex Bolt | Titanium Gr. 2 Stud Bolt |

| ASTM B348 Gr 2 Hex Bolts | ASTM B348 CP Grade 2 Nut Bolt |

| Titanium Grade 2 Hex Head Nuts | Titanium Grade 2 Square Bolts |

| Titanium Grade 2 Eye Bolts | Titanium Grade 2 T-Bolts |

| Titanium Grade 2 Bolts | Titanium Gr.2 Nuts |