Hardness testing to ISO 6508-1

Call anytime

Call anytime

Send email

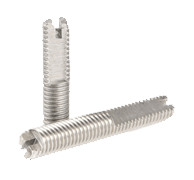

A Monel 400 manway stud refers to a threaded fastener made from Monel 400, a nickel-copper alloy known for its exceptional corrosion resistance and high strength. Manway studs are typically used in industrial equipment and systems to secure manway doors, hatches, or covers on vessels or containers, providing a means of access and inspection.

Here are the key features and information regarding Monel 400 manway studs:

Features of Monel 400 Manway Studs:

1.Material: Monel 400 is a nickel-copper alloy that contains approximately

67% nickel and 30% copper. It also includes small amounts of other elements like

iron and manganese. This alloy is renowned for its excellent resistance to

various corrosive environments, including seawater, acids, and alkalis.

2.Corrosion Resistance: Monel 400 is highly resistant to corrosion,

making it an ideal material for use in applications where exposure to corrosive

substances is a concern. It is particularly well-suited for marine and chemical

processing environments.

3.High Strength: Monel 400 exhibits good mechanical strength, which is

essential for securing manway doors and maintaining a reliable seal.

4.Durability: Monel 400 is known for its durability and long service

life, even in harsh operating conditions.

5.Threaded Ends: Manway studs typically have threads at both ends to

allow for secure fastening using nuts and washers.

Applications of Monel 400 Manway Studs:

Manway studs made from Monel 400 are commonly used in various industries and applications, including:

1.Marine and Offshore: Monel 400 manway studs are employed in marine

vessels, offshore platforms, and shipping containers where exposure to seawater

and saltwater is common.

2.Chemical Processing: They are used in the chemical industry for

equipment such as storage tanks, reactors, and piping systems, where resistance

to corrosive chemicals is essential.

3.Oil and Gas Industry: Monel 400 manway studs are suitable for use in

oil and gas processing equipment, particularly in environments with sour gases

and corrosive substances.

4.Aerospace and Aircraft: In the aerospace and aircraft industry, Monel

400 may be used in specific applications requiring resistance to corrosion and

high-stress conditions.

5.Food Processing: In food and beverage processing equipment, where

sanitation and corrosion resistance are crucial, Monel 400 manway studs may find

use.

| Specifications | ASTM B164 / ASME SB 164 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | D, Square,Round Etc. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

Selecting Monel 400 manway studs for your application depends on factors like load-bearing capacity, exposure to corrosive substances, and environmental conditions. It's important to consult with manufacturers or engineers experienced in materials selection to ensure you choose the appropriate fasteners for your specific needs. Proper installation and maintenance practices should also be followed to ensure the longevity and effectiveness of Monel 400 manway studs in your equipment or systems.

To preserve the high standards of our selection of industrial manway studs, we have always adhered to a systematic quality management process.

Our staff of experts is vibrant and talented, and they have always been our largest supporters and contributors to our success. Our vision is to create a world of manway studs.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Hardness testing to ISO 6508-1

Nut proof load testing to ISO 898-2

Suitability for preloading to EN 14399-2

Calibrated gauges and tools

| 400 Monel Manway Studs | Monel 400 Manway Stud Suppliers in Mumbai |

| 400 Monel Manway Stud Manufacturer in India | Best Monel 400 Manway Studs |

| 1.4301 Manway Studs | Monel 400 Manway Stud Price List |

| Monel 400 Manway Stud Supplier in India | Monel 400 Manway Studs Price List |

| Monel 400 Manway Stud Suppliers in India | Monel 400 Manway Studs Manufacturer in India |

| 400 Monel Manway Stud Manufacturer in Mumbai | ASTM B164 400 Monel Manway Stud |

| Monel 400 Manway Studs Manufacturers in Mumbai | 400 Monel Manway Studs |

| UNS N04400 Manway Studs | Monel 400 Manway Studs Manufacturer in Mumbai |

| Monel 400 Manway Stud Supplier in Mumbai | 400 Monel Manway Stud Manufacturer |