Hardness testing to ISO 6508-1

Call anytime

Call anytime

Send email

Incoloy is a metal alloy that exhibits high resistance to corrosion, and it is widely used in various industrial applications. Of all Incoloy materials, Incoloy 825 is considered one of the most versatile and widely used due to its exceptional properties. Manufacturers use Incoloy 825 to make fasteners, crucial mechanical devices that help connect two or more components. Incoloy 825 fasteners resist corrosion, heat, and chemicals, making them ideal for high-pressure environments.

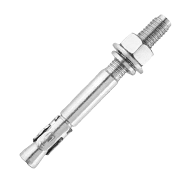

The most common Incoloy 825 fasteners include screws, nuts, washers, and bolts. Screws are threaded fasteners that turn into drilled or tapped holes. On the other hand, nuts are fasteners that provide secure threading for screws or bolts. Washers are thin sheets of metal or plastic that distribute the load of fasteners, while bolts are threaded fasteners that pass through drilled holes in different components to hold them together.

Incoloy 825 fasteners have various applications in different industries, including marine, oil and gas, chemical processing, food processing, and water treatment plants. Incoloy 825 fasteners are essential in marine and offshore environments in mooring systems, seawater piping, and heat exchangers. Incoloy 825 fasteners are used in reactors and chemical storage tanks in the chemical processing industry.

Incoloy 825 fasteners can fasten materials such as stainless steel, aluminum, and other metal alloys. They are also used in valves, pumps, flanges, and heat exchangers. Incoloy 825 fasteners are used in high-temperature applications such as furnaces, boilers, and heat exchangers.

Incoloy 825 fasteners offer several benefits to manufacturers and end-users. They resist corrosion, ensuring the fasteners last longer. They can withstand high pressure and temperature, making them suitable for harsh environments. Incoloy 825 fasteners are non-magnetic, making them ideal for applications where magnetism is undesirable. Incoloy 825 fasteners are easy to machine, making them ideal for mass production.

| Specifications | ASTM B425, ASME SB425 |

| Standard | DIN, ASTM, BS and all International Standards |

| Size | M3 to M90 |

| Length | 10mm to 1000mm |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

Incoloy 825 fasteners are mechanical devices used in various industrial applications. They exhibit superior resistance to corrosion, heat, and chemicals, making them ideal for high-pressure and harsh environments. Some of the common types of Incoloy 825 fasteners include screws, nuts, washers, and bolts. Their varied and extensive applications include marine, chemical processing, and offshore environments. Manufacturers and end-users of Incoloy 825 fasteners benefit from the fasteners' superior resistance to corrosion, ability to withstand high pressure and temperature, and non-magnetic properties.

To preserve the high standards of our selection of industrial fasteners, we have always adhered to a systematic quality management process.

Our staff of experts is vibrant and talented, and they have always been our largest supporters and contributors to our success. Our vision is to create a world of fasteners.

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Alloy 825 | N08825 | 2.4858 | NFE30C20DUM | NiCr 21 Mo | NCF 825 | NA 16 | ЭП703 | XH38BT |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Hardness testing to ISO 6508-1

Nut proof load testing to ISO 898-2

Suitability for preloading to EN 14399-2

Calibrated gauges and tools

| Inconel 825 Spring Washer | Nickel Alloy 825 Fasteners |

| Alloy 825 Fasteners Manufacturer in India | Best Incoloy 825 Fasteners |

| ASTM B425 Alloy 825 Fasteners | M6 Inconel 825 Washers |

| 825 Alloy Fasteners | Incoloy 825 Fasteners Suppliers in Mumbai |

| UNS N08825 Fasteners | Incoloy 825 Fasteners Manufacturer in Mumbai |

| Alloy 825 Nut Bolt Price List | Alloy 825 Marine Fasteners |

| Alloy 825 Fasteners Manufacturers in Mumbai | A4 Incoloy 825 Hex Bolt |

| Incoloy 825 Fasteners Suppliers in India | Incoloy 825 Fasteners Manufacturer in India |

| 2.4858 Fasteners | Inconel 825 Anchor Bolt |

| Incoloy 825 Fasteners Supplier in India | Alloy 825 Fasteners Price List |

| Alloy 825 Fasteners Supplier in Mumbai | Inconel 825 Bolts and Nuts |