Hardness testing to ISO 6508-1

Call anytime

Call anytime

Send email

Inconel 625 Flat Washers and Spring Washers, designated as UNS N06625, are specialized types of washers made from the Inconel 625 alloy. Like other Inconel 625 products, these washers are highly corrosion-resistant and exhibit excellent mechanical properties, making them suitable for use in demanding and corrosive environments.

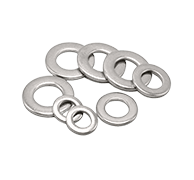

Inconel 625 Flat Washers (UNS N06625): Flat washers are used to distribute the load or pressure of a threaded fastener (such as a bolt or screw) over a larger surface area. Inconel 625 flat washers are used in applications where corrosion resistance, high strength, and resistance to high-temperature environments are essential. Some common applications include:

Aerospace: Inconel 625 flat washers are used in the aerospace industry for various applications, including aircraft engine components and assemblies.

Chemical Processing: They find use in equipment and pipelines in chemical processing industries to prevent leaks and maintain structural integrity in corrosive environments.

Oil and Gas: Inconel 625 flat washers are used in oil and gas processing facilities, including offshore platforms and pipelines, where exposure to seawater and harsh chemicals is a concern.

Power Generation: They are used in components like gas turbine assemblies and nuclear reactor systems due to their ability to withstand high temperatures.

Marine Industry: Inconel 625 flat washers are used in marine applications for their corrosion resistance in saltwater environments.

| Standard | : | ASTM A166 / SA166 |

| Dimension | : | ASTM,DIN, BS,GB, IS and all International Standards |

| Diameter | : | M2 to M100 |

| Heat Treatment | : | Annealing, Stress Relieving, Case Hardening, Quenching and Tempering. |

| Type | : | Plain Washer, Spring Washer, Tooth Washer, Tapper Washer, Tab Washer, Star Washer etc. |

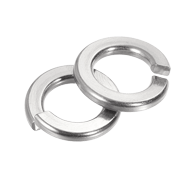

Inconel 625 Spring Washers (UNS N06625): Spring washers, also known as Belleville washers, are designed to provide a spring-like action, which helps maintain tension and prevent loosening in fastener assemblies. Inconel 625 spring washers are specifically chosen for applications where resistance to corrosion, temperature fluctuations, and vibration is necessary. Common applications include:

High-Temperature Bolting: Inconel 625 spring washers are used in conjunction with high-temperature fasteners like bolts and nuts in applications where thermal expansion and contraction are a concern.

Pressure Vessels: They are employed in pressure vessel applications, such as those used in the chemical and petrochemical industries, to ensure a secure and leak-free seal.

Valve Assemblies: Inconel 625 spring washers can be found in valve assemblies where the ability to withstand high pressures and temperature variations is essential.

Pump Systems: Inconel 625 spring washers are used in pump systems to provide a reliable and leak-resistant seal.

When selecting Inconel 625 washers, it's important to consider the specific requirements of your application, including size, thickness, and load-bearing capacity. Proper installation and torque specifications should be followed to ensure the washers perform as intended, maintaining the integrity and reliability of the fastener assembly in corrosive and high-temperature environments.

To preserve the high standards of our selection of industrial washers, we have always adhered to a systematic quality management process.

Our staff of experts is vibrant and talented, and they have always been our largest supporters and contributors to our success. Our vision is to create a world of washers.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | N600DNB4M | NiCr22Mo9Nb |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | - | 5.0 max | 58.0 min | 20.0 - 23.0 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Hardness testing to ISO 6508-1

Nut proof load testing to ISO 898-2

Suitability for preloading to EN 14399-2

Calibrated gauges and tools

| Inconel® Alloy 625 Conical Spring Washer | Inconel 625 Disc Spring Washer Manufacturer in Mumbai |

| Inconel 625 Class 10 Knurled Flat Washer Supplier in India | 625 Inconel Grade 8 High Collar Flat Surface Washer Price List |

| Nickel Alloy 625 Helical Spring Washer | Inconel 625 M8 Spring Washer |

| 2.4856 Flat & Spring Washers | Inconel 625 Thin Flat Washer |

| 625 Inconel Spring Washer | Inconel Alloy 625 Disc Spring Washer Suppliers in Mumbai |

| Inconel 625 Plain Washer | Inconel® Alloy 625 Spring Washer |

| Alloy 625 Square Spring Washer Manufacturer in India | Inconel Alloy 625 Thick Flat Washer |

| Alloy 625 Flat Washers Manufacturer in Mumbai | Inconel 625 Flat and Spring Washers |

| UNS N06625 Flat & Spring Wahers | Inconel 625 Split Spring Washer Manufacturer in Mumbai |

| Inconel 625 Grade B8 Class 2 USS Flat Washer Supplier in Mumbai | 625 Inconel 8.8 Grade Knurled Flat Washer Manufacturer |

| Alloy 625 Plain Washer Suppliers in India | Inconel 625 Curved Spring Washer Manufacturer in India |

| ASTM A166 Inconel 625 High Collar Flat Washer ISO 7089 | Nickel Alloy 625 SAE Flat Washer |