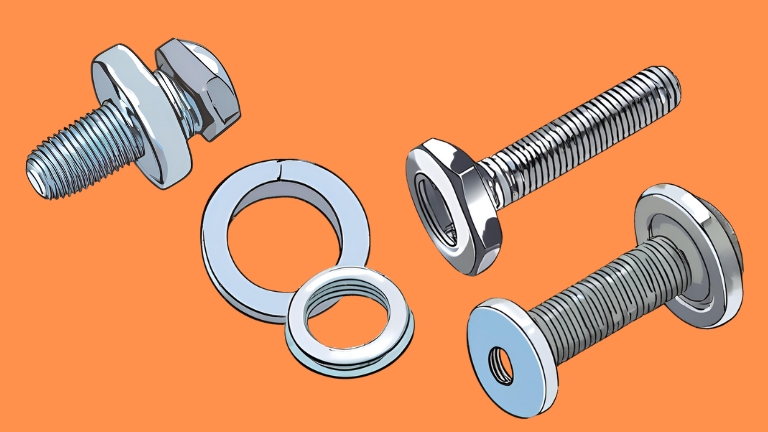

Spring steel washers are integral components in various mechanical applications, engineered to provide tension, prevent loosening, and maintain the integrity of fastening systems. These washers are crafted from high-carbon, heat-treated steel, giving them exceptional elasticity and durability. They are widely used in industries where dynamic loads, vibration, or fluctuating forces may cause fasteners to loosen over time. The primary function of spring stainless steel washers is to absorb shock, distribute loads evenly, and retain the necessary tension to secure fastened components.

Main Applications of Spring Steel Washers

Preventing Loosening in Mechanical Assemblies

Spring washers are crucial in environments with constant movement or vibration, such as automotive engines, aerospace systems, and heavy machinery. For instance, SS 304 spring washers are widely used due to their excellent corrosion resistance and durability in general-purpose industrial applications, especially in sectors like food processing and construction. In high-temperature environments, SS 310 spring washers are favored for their oxidation resistance, ensuring stability even in extreme heat conditions like furnaces or exhaust systems.

Shock Absorption

Spring steel washers excel at absorbing vibrations and shock, making them ideal for systems subject to dynamic loads, such as suspension systems or heavy-duty industrial machinery. For applications in marine environments or chemical plants, SS 316 spring washers are commonly used due to their enhanced resistance to corrosion from saltwater and harsh chemicals. Similarly, SS 317L spring washers provide extra protection in sulfuric acid environments, making them suitable for chemical processing equipment and petrochemical facilities.

Maintaining Tension in Bolted Connections

Maintaining consistent tension in bolted assemblies is vital to prevent loosening due to material relaxation over time. SS 321 spring washers, stabilized with titanium, are often used in aerospace and high-temperature applications where welding might weaken the structure. These washers ensure that the assembly remains securely fastened, even in challenging conditions. For applications requiring resistance to oxidation and temperature fluctuations, SS 347 spring washers are used in systems like gas turbines and heat exchangers.

Load Distribution

Apart from maintaining tension, spring washers also help distribute load across the fastened surfaces, preventing deformation or damage to softer materials. SS 410 spring washers, known for their strength and hardness, are perfect for applications that endure mechanical wear, such as pumps and valves. In aggressive chemical environments, SS 904L spring washers are highly effective due to their excellent resistance to sulfuric and phosphoric acids, making them indispensable in chemical processing industries.

Conclusion

Spring steel washers play an essential role in fastening systems across various industries by preventing loosening, absorbing shock, and distributing loads. With a range of stainless steel grades available, including SS 304, SS 316, SS 321, and SS 904L, these washers are tailored to meet the specific needs of environments ranging from general industrial use to highly corrosive or high-temperature settings. Their versatility and durability make them a crucial component in ensuring the long-term stability and performance of mechanical assemblies.